The production and processing of marble involve a series of meticulous steps, transforming raw stone into the polished slabs and tiles admired in architectural and design projects around the world. Here's an overview of the process in English:

1. Quarrying: The journey begins at marble quarries where the stone is extracted from the earth. This step involves the use of specialized equipment and techniques, such as diamond wire saws and drilling equipment, to carefully cut and remove large blocks of marble from the ground, ensuring minimal damage to the environment and the stone.

2. Block Dressing: Once extracted, the large blocks are inspected for quality and then cut into more manageable sizes using gang saws or block cutters. This process is crucial for facilitating the transportation of marble and preparing it for further refinement.

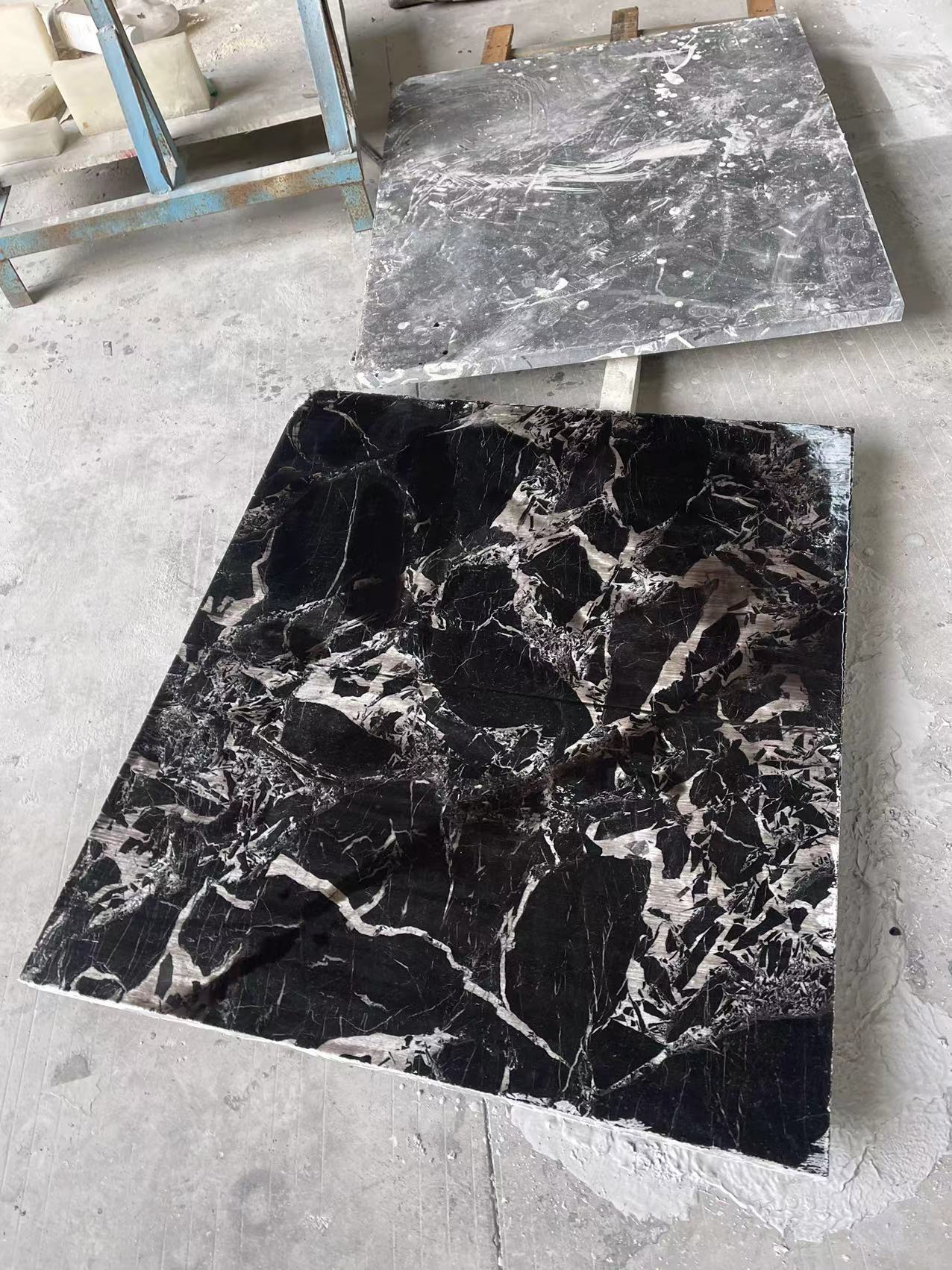

3. Slab Cutting: The dressed blocks are then sliced into slabs of varying thickness using high-precision machinery. The thickness of the slabs depends on their intended use, with thinner slabs for tiles and thicker ones for countertops and other applications.

4. Polishing: After cutting, the slabs are polished to achieve the desired finish. Polishing enhances the natural patterns and colors of the marble, making each piece unique. The level of polish can range from matte to high gloss, depending on the customer's preference.

5. Resin Application: To strengthen the slabs and fill in any natural imperfections, a resin is often applied to the surface of the marble. This process not only improves the durability of the marble but also enhances its beauty.

6. Cutting to Size and Finishing: The polished slabs are then cut to specific sizes and shapes according to project requirements. This step may involve additional detailing, such as edging and shaping, to meet the precise design specifications.

7. Quality Control: Throughout the production process, rigorous quality control measures are in place to ensure that only the highest quality marble reaches the customer. This includes inspections for cracks, color uniformity, and polish quality.

8. Packaging and Shipping: Finally, the finished marble products are carefully packaged to prevent damage during transportation and shipped to clients worldwide, ready to be installed in homes, offices, and public spaces.

The marble production process is a testament to the blend of tradition and technology, bringing the timeless beauty of natural stone to life.